Our multi-axis machines allow for movement in four or more axis during a machining process. This process has various benefits to our customers: decrease in machine time, less number of set ups, better finish part quality, and higher part precision. Each benefit allows for us to reduce your overall cost and lead time.

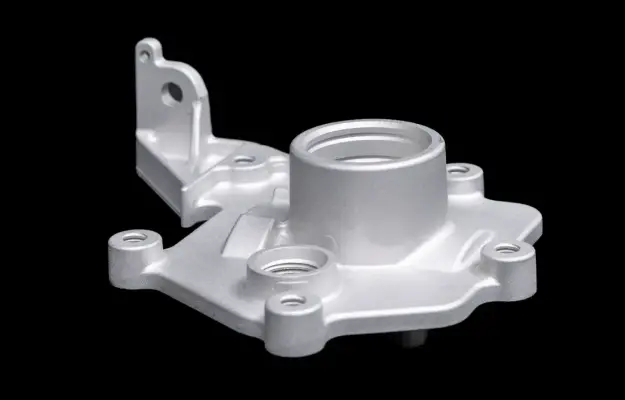

5-Axis Machines

These machines allow us to machine parts with complex shapes and angles in one setup. These machines use shorter cutting tools that allow higher cutting speeds with less tool vibrations for higher precision.

Details

| Brand | Model | Axis | X-Axis Travel | Y-Axis Travel | Z-Axis Travel | Comments |

|---|---|---|---|---|---|---|

| DMG | DMU105 | 5 | 44.50" | 41.00" | 29.50" | Full 5 Axis/ 12,000 RMP/ 4,500 lb. Table Capacity |

| DMG | DMU65 | 5 | 25.50" | 25.50" | 22.00" | Full 5 Axis/ 18,000 RMP/ 1,200 lb. Table Capacity |

| DMG | CMX50 | 3+2 | 19.70" | 17.70" | 15.70" | 18,000 RPM |

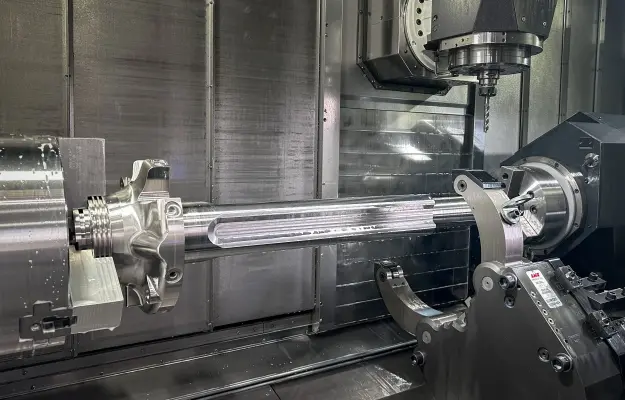

Mill-Turn Machines

These machines delivers maximum versatility for small to large parts. It combines the capabilities of a high-powered turning center and full-function machine center to produce parts in a single setup. We are capable of holding +/- 0.0003 on diameter and +/-0.0005 on location and size.

Details

| Brand | Model | Comments | |||||

|---|---|---|---|---|---|---|---|

| Okuma | Multus | Dual Spindle | X-25.50" | Y-11.80" | Z-78.74" | ||

| U4000 | Main Spindle | 4.41" thru | 15" chuck | 2800 RMP | |||

| 2SW/2000 | Sub Spindle | 10" chuck | 4200 RMP | ||||

| Mill Spindle | 12000 RMP | Full 5-Axis | |||||

| Lower Turret | 12 Station | Steady Rest Ready | |||||

| Mazak | 300 ll SY | Dual Spindle | X-24.00" | Y-9.00" | Z-38.00" | ||

| Main Spindle | 3" thru | 15" chuck | 1800 RMP | ||||

| Sub Spindle | 10" chuck | 3600 RMP | |||||

| Mill Spindle | 1000 RMP |